CAPILASIL®

CAPILASIL® is a range of colorless water repellents designed for walls and facades, created to provide maximum protection against surface or rising moisture problems.

Cleaning the building with a water repellent is one of the first steps in a renovation project. CAPILASIL® water repellents allow your "hydrophilic" materials to become "hydrophobic" while maintaining their water vapour permeability.

Depending on your needs and the nature of your moisture problems, the formulas in the CAPILASIL® range vary to ensure maximum success in your façade renovation, patio and rising damp projects.

CAPILASIL® - your water repellent solution against moisture

With the CAPILASIL® range of water repellents, you can start your projects on the right footing - dry and healthy rooms. With moisture-protected walls and facades, you are free to consider all types of development and renovation.

If you do not see the automatic video, click this link: Video

Benefits of CAPILASIL® water repellent solutions

- Protects external walls from rain.

- Prevents frost damage and therefore cracks.

- Allows materials to continue to "breathe", limiting condensation humidity inside.

- Promotes savings on heating costs, as dry materials have better thermal insulation than wet ones.

- Reduces moss and mould formation and prevents leaching.

- Maintains clean facades.

- Prevents the formation of salts.

A QUIET DRESS

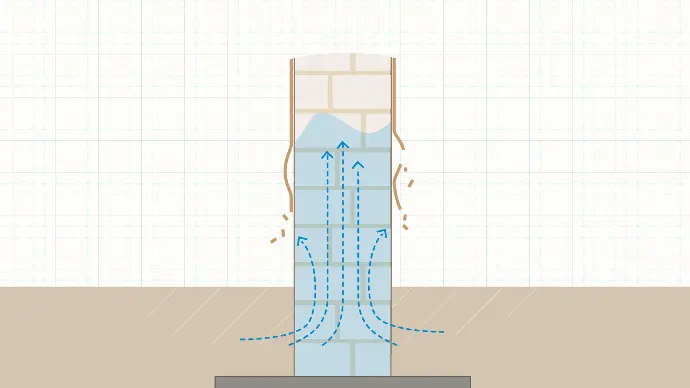

This type of moisture is caused by capillary water absorption.

When the capillaries are thin, moisture migrates slowly, but the pressure is high and the moisture rises up to two metres. When the capillaries are larger, the moisture migrates faster but the pressure is lower. The rising humidity is usually between 80 cm and one metre high.

CAPILASIL® solutions are injected and form a hydrophobic barrier at the bottom of walls. In the water or solvent phase, they allow drying and protect the walls from rising damp.

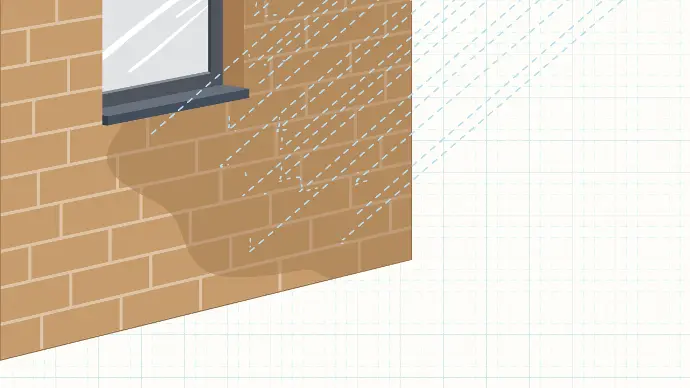

SURFACE HUMIDITY

Our surface water repellents are designed to treat most surfaces made of porous materials (walls, seams, etc.). CAPILASIL® solutions have exceptional water vapour permeability and ensure waterproofing of treated materials.

Brick, concrete, stone or even wood: whatever type of surface you want to protect from water, there is a CAPILASIL® solution to suit.

Application

CAPILASIL® water repellent solutions are applied using an injection pump (available for hire) and a special method.

Practical studies prove that the injection treatment of buildings against rising damp with CAPILASIL® water repellent solutions, which started more than 40 years ago, is still effective and will continue to be for a long time. With treatment and injection according to our technical data sheets, your buildings will be protected and remain healthy in the long term.

Features

CAPILASIL® water-repellent solutions, both in solvent and aqueous form, are made of oligomeric siloxanes containing high concentrations of active ingredients. This product has a hydrophobic effect, excellent penetrating power and very good activity, even in the presence of harmful salts such as nitrates with a "curing" factor.

We also offer solutions for treating wood against moisture by impregnation.

Packaging

CAPILASIL® solutions are available in 5 and 25 litre drums (canisters). The consumption is between 1.5 and 2 litres per running metre with a penetration depth of up to 10 cm.

Dažniausiai užduodami klausimai

Šiek tiek informacijos apie CAPILASIL®

"Beal is the only manufacturer of the CAPILASIL® product range to have registered this name. We advise you to beware of imitations and counterfeits as they do not meet the same quality requirements.

BEAL INTERNATIONAL products, in particular MORTEX®, BEALSTONE® and CAPILASIL®, are protected products. They meet stringent quality requirements, the results of which BEAL INTERNATIONAL is committed to guaranteeing. BEAL INTERNATIONAL is the sole manufacturer of its products.

The products are distributed in Lithuania by BEAL INTERNATIONAL official representative MB Girinė

Many competing companies seek to take advantage of the reputation of BEAL INTERNATIONAL and its products in order to mislead the consumer, without shying away from using deceptive, misleading or disparaging means to sell products of significantly inferior or unauthorised quality. Please remain alert to any counterfeits or imitations and, if necessary, inform the management by e-mail info@girine.lt or info@beal.be.

The CAPILASIL® range is a range of water repellents (repellent - water repellent) in aqueous and/or solvent phase.

CAPILASIL® water repellents are products based on oligomeric siloxanes in the form of very small molecules. Due to their small size, these molecules do not tend to block pores. The most concentrated solution (10% of active ingredients based on 100% concentrate) blocks the pores by only 2%, i.e. very slightly.

When using solvent-based CAPILASIL® , always take care to avoid contact with solvent-sensitive materials (insulation, roofing, asphalt etc.).

Avoid using CAPILASIL® aqueous phase on surfaces that are already waterproof, as the product will repel any waterproof base.

Make sure the substrate is dry to ensure ideal penetration.

Spraying of the product (especially solvent-based products) is not recommended. The water or organic solvents in these products will tend to evaporate and will not perform their role perfectly in the wall. In fact, water or solvents are the 'transport' agents for the active substances, which are necessary for the substrate in order to ensure perfect diffusion, which is always the basis for a successful effect.

Therefore, we use heavy organic solvents (mainly aromatic) in solvent solutions, which, due to their slow evaporation, help the product spread well into the substrate. This is an additional advantage that ensures an effective process.

Two different CAPILASIL® products for injection and façade protection.

1. Solvent phase :

BEAL produces CAPILASIL® in a solvent phase based on oligomeric siloxanes (10% concentration) as active ingredients, using a high quality and high performance unflavoured solvent.

Aromatic substances are largely removed, but some remain.

The solvent is heavy to allow further dispersion after injection. The solvent then evaporates and gives way to the oligomeric siloxane system barrier formed by polymerisation.

The solvent is the carrier of the product. It is non-polar and therefore does not mix with water. Initially the solvent acts as a barrier, and as soon as it evaporates, polymerisation takes place and a true barrier is formed (barrier effective on the day of injection). Any moisture present in the substrate is an accelerating factor for polymerisation.

Do not use this "solvent" substrate if there are solvent-sensitive elements in the walls, floors and under the screed or concrete, etc. In this case CAPILASIL HEH2O (water-based) should be used.

During the cold season, provide additional heating and ventilation of the treated areas to evaporate any un-evaporated solvents and moisture still present in the walls. Naturally, as the products are heated, the last aromatic substances still present in the products will give off more odour. Therefore, heaters significantly enhance the odour of the remaining aromatics (e.g. heating a cold sauce releases aromatics).

The drying time depends on the components of the wall coverings (paint, plaster, lime, cement, tiles, etc.), the heating (during cold periods) and the ventilation equipment in the rooms.

For uncoated walls, this usually takes 6 months to a year and a half or even longer. In the early stages, on sites exposed to the wind (without framing), the surface would dry in about 2.5 or 3 months.

2. The aqueous phase:

BEAL produces CAPILASIL® HEH20 based on siloxanes diluted in water.

The advantage of this type of product is that it is completely odourless.

On the other hand, it should be noted that injection into walls or foundations also introduces a significant amount of water, which is necessary for siloxane diffusion. This water will also have to evaporate. The drying process will therefore be much longer than with a solvent-based product, where the solvent evaporates more easily. In addition, additional salts will be formed as water is added in large quantities to the alkaline medium.

The barrier does not work on the day of the injection, but much later. Siloxanes start to polymerise as water evaporates, so polymerisation is slow. Polymerisation usually starts after a month, and sooner in high heat.

There is also a risk that the barrier will rise with rising humidity and be diluted before polymerisation occurs.

Polymerised siloxanes will then be effective after all water in the products and walls has evaporated. The drying time depends on the components of the wall covering (paint, plaster, lime, cement, tiles, etc.), heating (in cold periods) and ventilation. It is therefore dependent on the installation of the premises.

For uncoated walls, this usually takes between 6 months and two years.

Much faster drying was observed in open areas exposed to the wind (no frames). After 10 months, convincing results were observed

All moisture problems are caused by capillary action, i.e. the action of capillaries in materials, except of course for the direct entry of water.

Pay special attention to how professionals tell you about rising humidity!

There are indeed several devices on the market, the most commercially available being a device that passes energy between two electrodes. Since water is a 'good conductor', the measurement is made by setting the values on a scale corresponding to the percentage of moisture present in the walls. It should be noted that not only water is a conductor, but also the salts that are very often present in masonry: phosphates, sulphates, chlorides, etc.

Thus, electrode instruments may not be suitable for obtaining conclusive results on moisture content. These devices work by transferring energy between two electrodes. The wetter the medium, the higher the measurement result. However, it can also be confused by salts in a dry wall. Salts are conductive elements.

The only validated system is the CM method (carbide method). This instrument is available in our office with a pre-ordered technical explanation and deposit.

In some cases, chloride formation can be observed in houses close to roads that receive water with de-icing salts, or in houses in coastal sea areas.

In addition, nitrates can be formed as a result of the decomposition of organic matter (on farms, in old stables, etc.). Also watch out for bricks and porous reusable materials, which may contain nitrates depending on their origin.

In this type of building, the treatment of rising damp is one of the first operations that needs to be carried out in order to dry the walls more quickly, as the building is open to all winds.

The crystallization of salts is a common phenomenon, and these salts tend to build up, leading to delamination of the finish and even cracking of the materials themselves.

All salts are hygroscopic and retain water. After the treatments that are effective in the injection area, there may still be areas of masonry above the injection barrier that contain salts, particularly nitrates. At high concentrations, these salts can cause damage (moisture stains) in very specific areas and this will no longer have anything to do with the moisture problems that arise.

The presence of these salts can also be a very influential factor in determining the true source of moisture.

After the rising damp has been cleaned out, any remaining water in the walls still needs to be removed by evaporation. Since salts are soluble, water acts as a "carrier" for the salts that remain on the surface after evaporation.

Other systems are available to overcome this problem, such as the MORTEX NO3 coating. For more information on this problem, please contact us. Manufactured to order, depending on availability of raw materials.

The walls contain capillaries and the surface tension is characteristic of the materials they contain. The role of a good injection agent is to leave a very high vapour permeability, but not to allow water to penetrate the capillaries. This barrier is achieved by varying the surface tension of the materials. Water will no longer pass through the capillaries and will be blocked at the point where the impregnation was carried out.

CAPILASIL® fulfils this function perfectly.

When injected in accordance with the specified requirements and installation instructions, it will provide a comprehensive result. The formulation is based on oligomeric siloxanes (10% active ingredients). This means that they are very small molecules that will only block a few pores, which is a very important characteristic.

Monomer-based silanes have even smaller molecules but are highly volatile, so a product based on 30-40% silane active ingredients would be needed to achieve a concentration of around 10% active ingredients on and in the walls. Polymers have an unpleasant tendency to block pores due to their large molecular size. As a result, they clog pores and capillaries, making vapor permeability very difficult.

Important: Salts, especially nitrates, can form a chain that further increases the moisture content after routine treatment.

To avoid this major complication, we suggest treating with CAPILASIL HS (solvent phase) when the nitrate content exceeds 3.5-4%.

To make this measurement, please mail or bring us at least 10 g of wall dust (the wettest and most porous areas). This wall dust shall be taken every 6 meters at the level of the future injection barrier on the same wall. Please check our requirements.

We will send you the results after the analysis.

It should be noted that in some cases the walls are thought to be affected by rising damp, when this is simply the effect of capillary joints or a lack of material between the skirting board and the tiles. As a result, cleaning water (or liquid accidentally spilled on the floor) may penetrate through solid or void material.

This is more pronounced if the last tile laid against the wall is slightly leaning against the wall. As the plaster is not very porous and the skirting board is impermeable to water, with each cleaning the water accumulation becomes more significant and can cause damage similar to that of the walls experiencing the same phenomenon. In this case, a simple silicone sealant such as MS Polymer can solve the problem. After applying the sealant, allow the wetted materials to dry thoroughly before repainting.