BEALSTONE®, your customized Terrazzo coating

You get what you want

Discover the BEALSTONE® system and be amazed by the combination of functionality and beauty. This is a necessary advantage for your property: easy to install, resistant and adaptable, Terrazzo will beautify your home.

Brochure

Quality TERRAZZO coating for creativity.

Unlimited possibilities

With so many application possibilities, few technical constraints and guaranteed stunning results, BEALSTONE® Terrazzo is the natural choice for those who have a taste for beauty and a practical approach to achieving it.

Architects, decorators and individuals can finally bring spaces to life the way they dreamed of: without restrictions.

BEALSTONE® Terrazzo, aesthetics and technology to renew your spaces

Refresh old coatings

BEALSTONE® floor, wall and furniture coverings are ideal for creating modern, seamless and smooth spaces with a distinctive Terrazzo style.

Its thickness can be adjusted to suit each project, from 2 mm to several centimetres. It can be preformed on site or prefabricated in the workshop and can be used to cover walls, floors and furniture both indoors and outdoors. It will retain its existing functional properties.

In any room, this Terrazzo coating fits perfectly into the surrounding décor, whether it's contemporary or vintage. Combining it with other materials - wood, metal, steel, etc. - makes it shine even more.

With BEALSTONE® products, old Terrazzo coatings can be restored and Art Deco coatings can be restored almost identically

BEALSTONE® Terrazzo your personality decorations that reveal your personality

Create

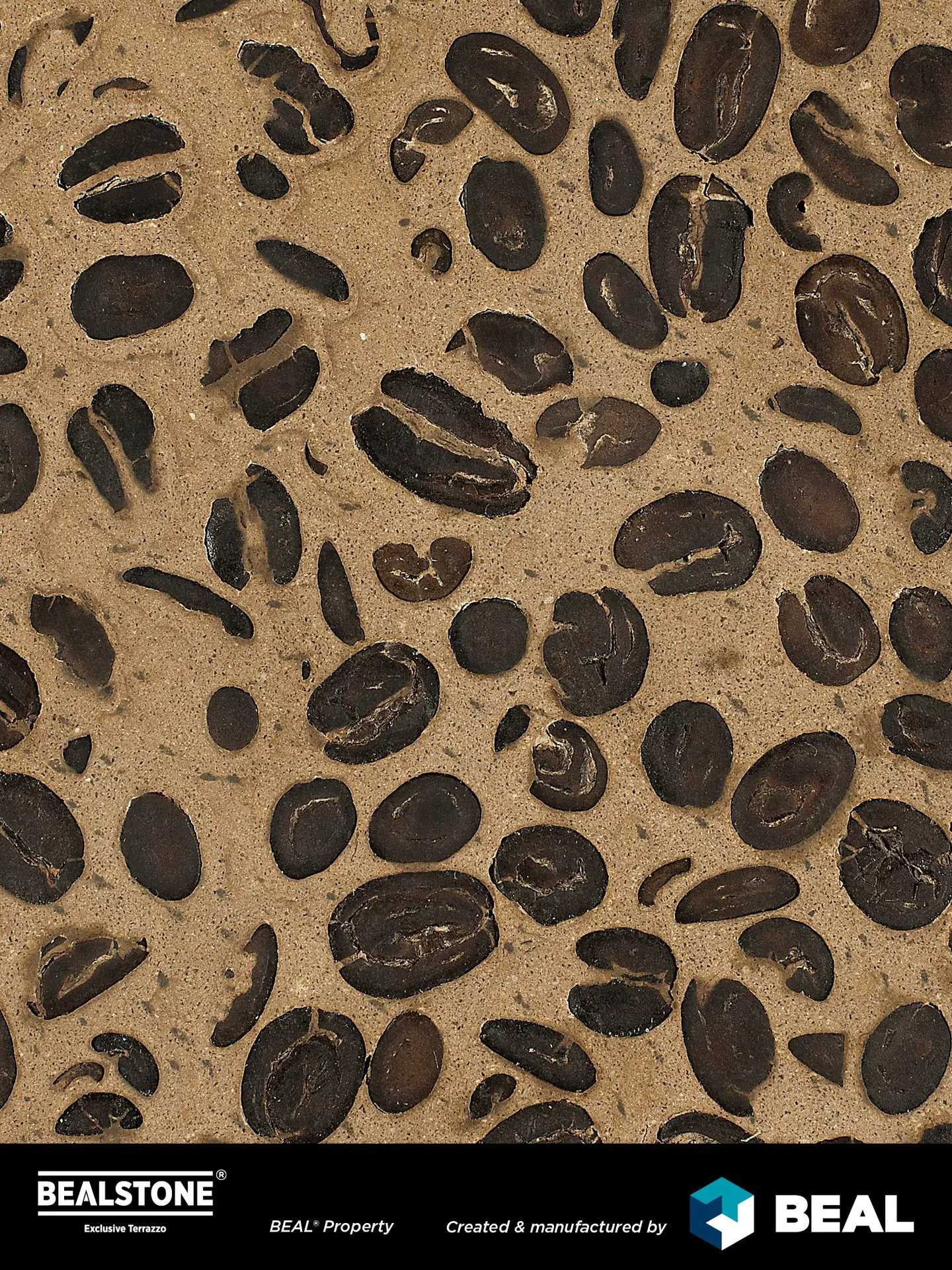

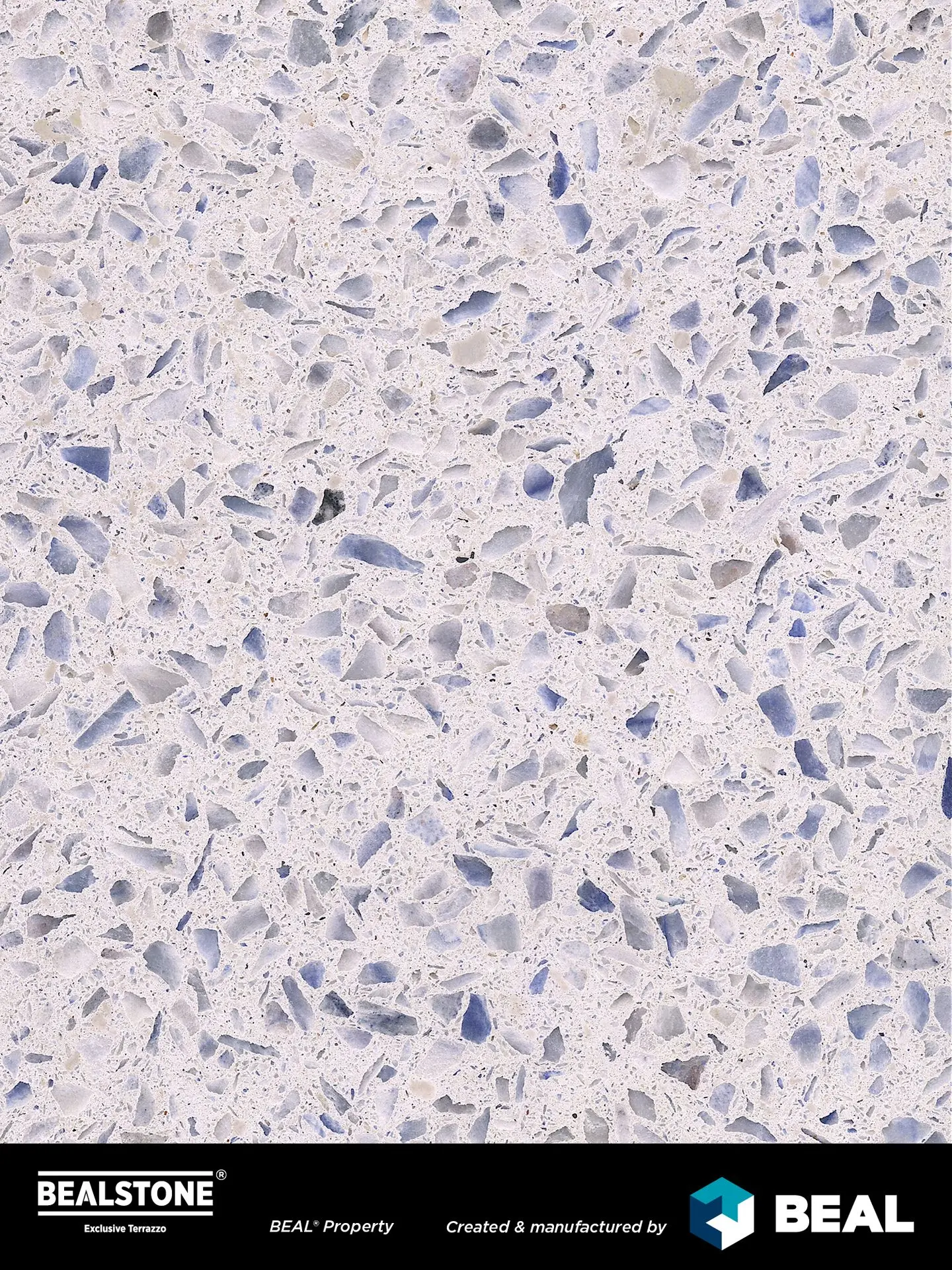

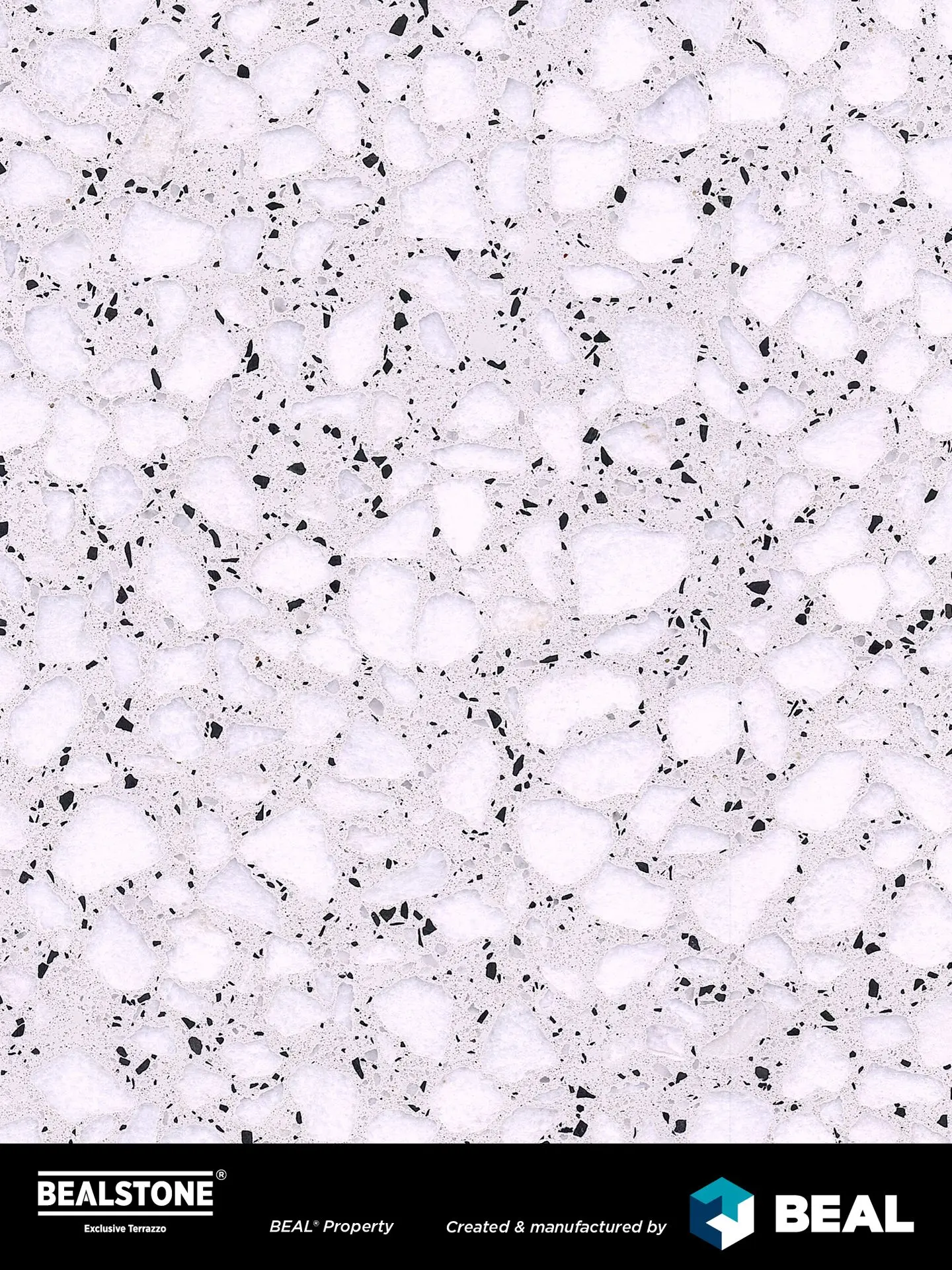

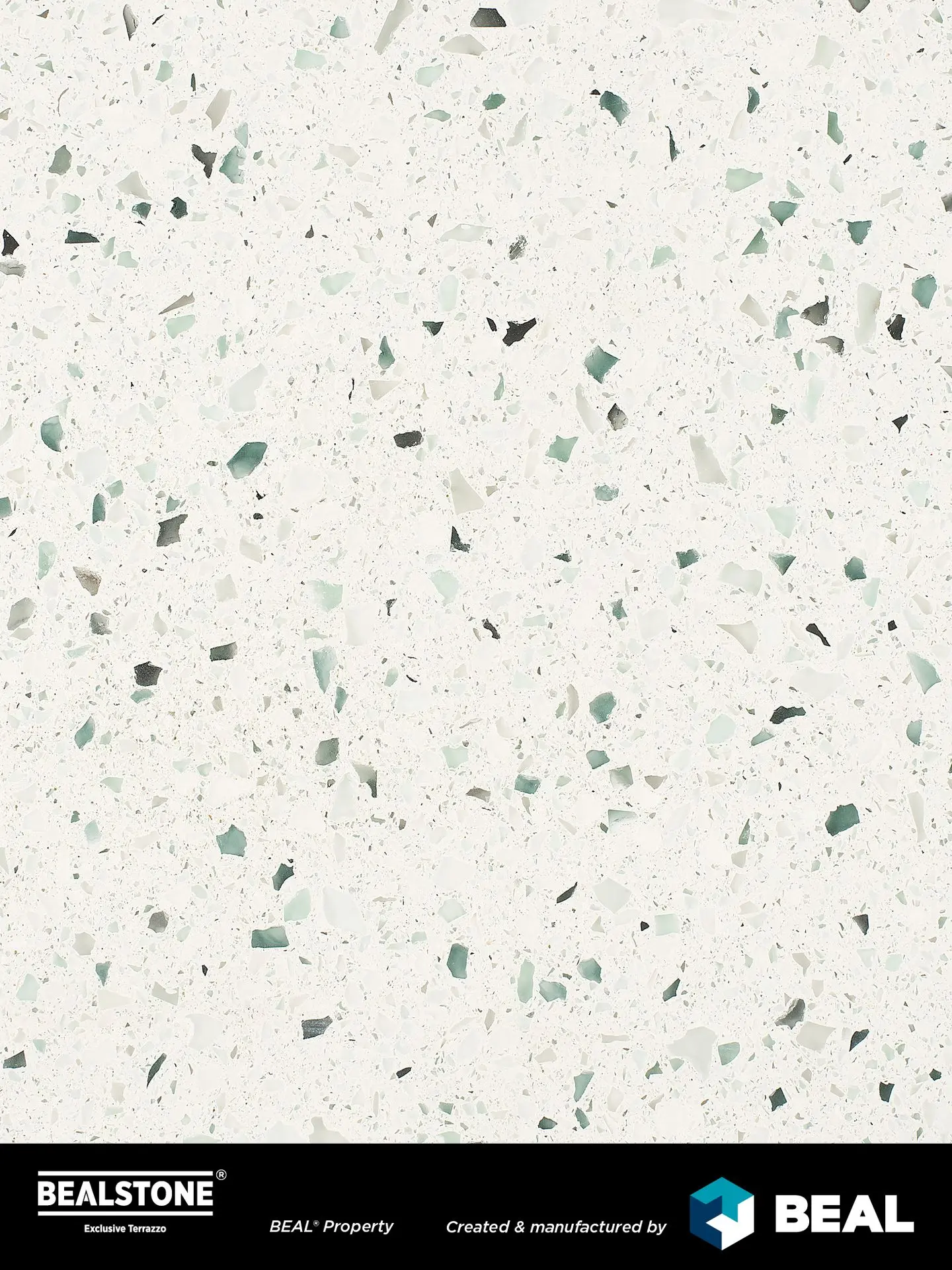

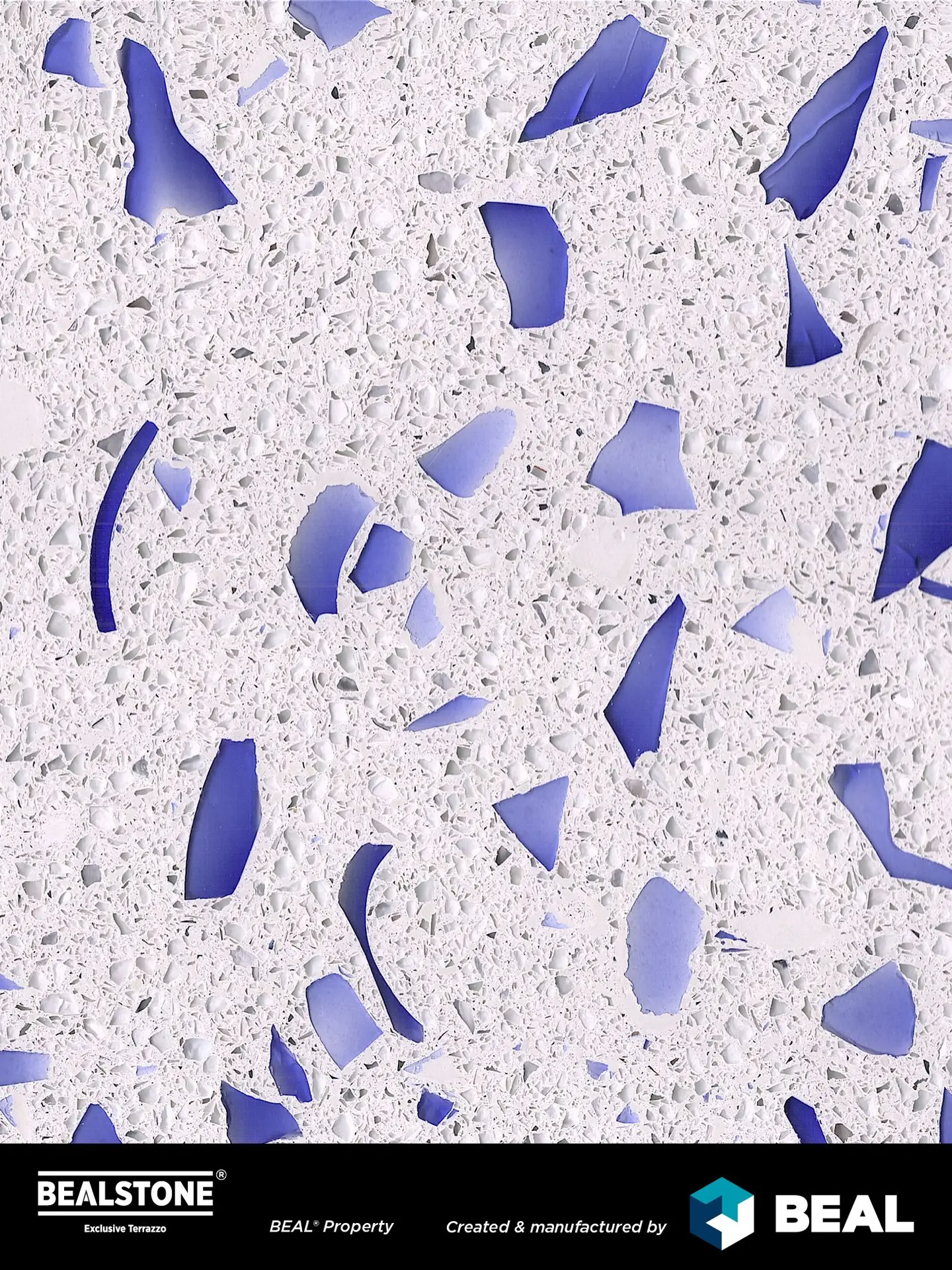

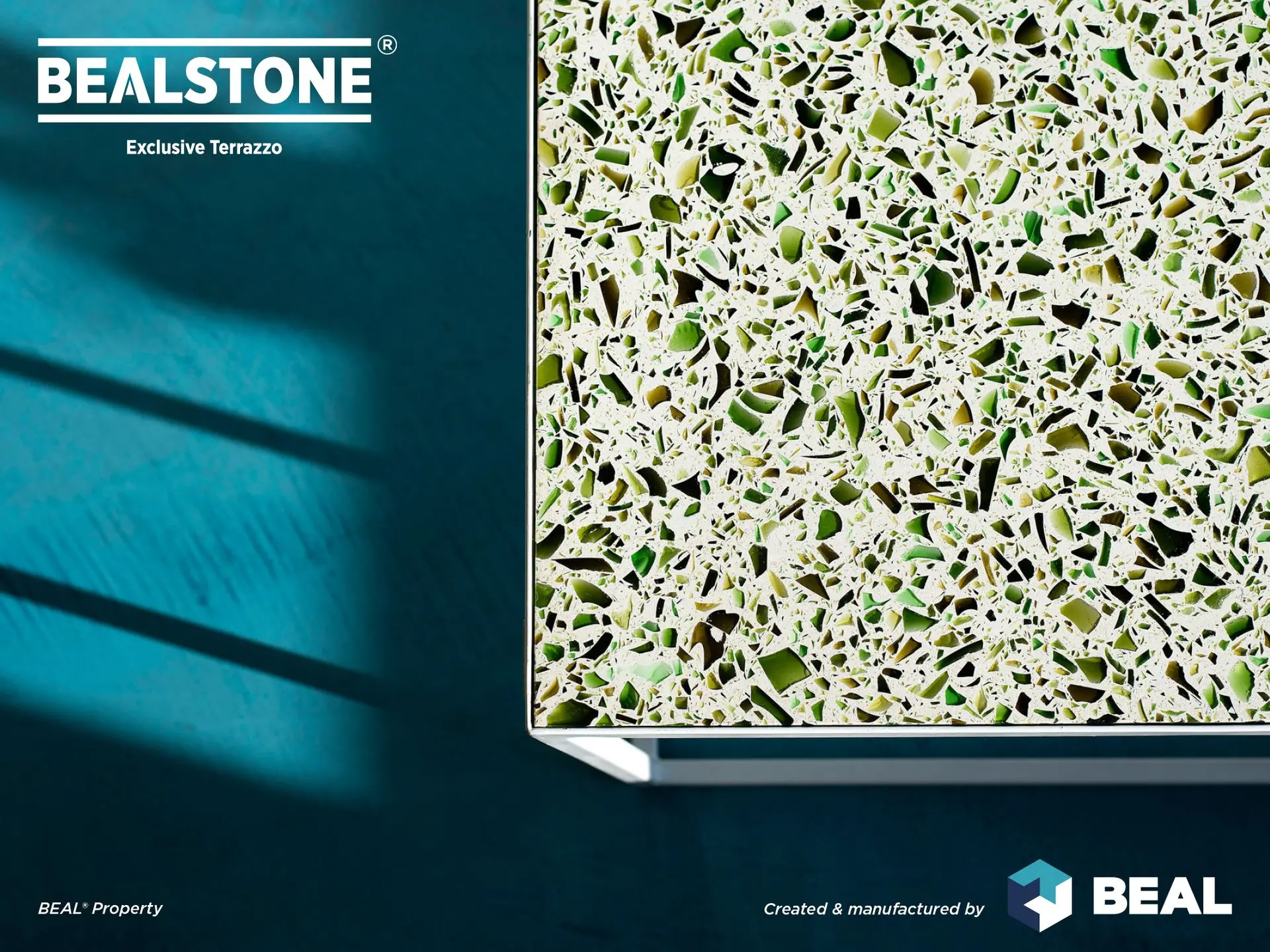

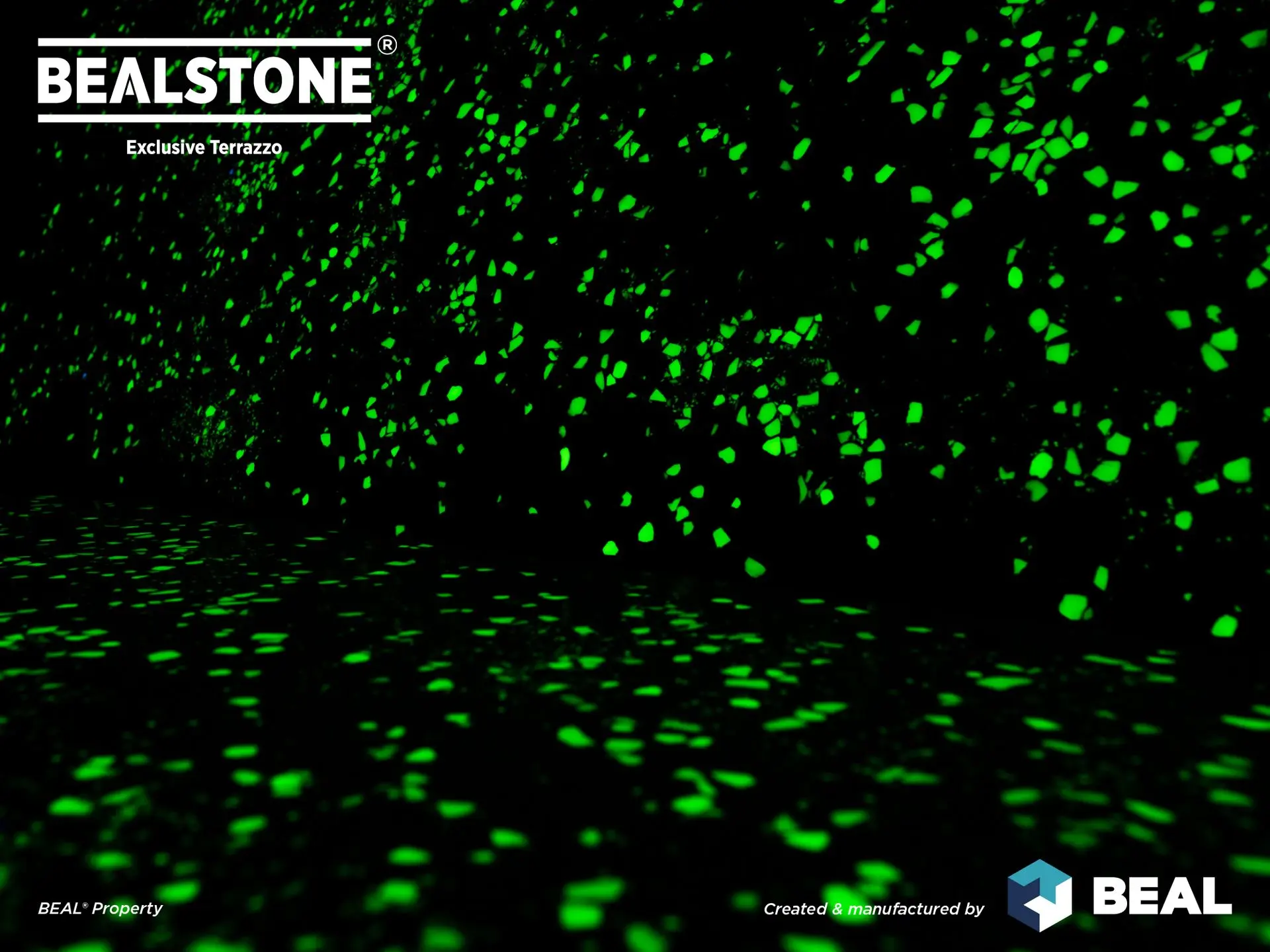

While the original Terrazzo from Italy is made from natural stone fragments and marble, the BEALSTONE® Terrazzo solution goes one step further and allows you to choose between different materials. Quartz, metal, marble, terracotta, precious stones, glass, shells, pebbles, mirror chips, small pebbles, silica grains, recycled materials... You choose the aggregate you want, only your imagination limits you!

The colour is also up to you. BEALSTONE® filament can be used to make endless colours. The only difficulty is to choose a shade from this infinite colour palette.

The incomparable benefits of BEALSTONE® Terrazzo

Resistance

All the components of BEALSTONE® Mineral Coating come together to form a highly resistant coating that gives the unique look of granite, also known as Terrazzo. Thanks to its high technical resistance, this material guarantees unrivalled durability.

Thin layer

BEALSTONE® Terrazzo can be adapted to all projects as it is used in very thin layers (from 2 mm to a few centimetres), making it essential for renovation works.

Adaptation

The neutral BEALSTONE® Terrazzo flooring base can be coloured with pigments to create an unparalleled individuality. All colours are available. The combinations of colours and fillers are endless and allow completely individual results.

Mineral

BEALSTONE® is distinguished from all other solutions on the market by its mineral appearance. Its texture ensures a natural, warm and high-quality result.

Adhesion

BEALSTONE® granite-based floor, wall and furniture coatings adhere to a wide range of surfaces (mineral, tiles, MDF...). Walls, floors and furniture, horizontal or vertical surfaces, interior or exterior: transform any space to your wishes.

Dry and/or wet sanding

BEALSTONE® Terrazzo can be dry-sanded to facilitate working in thin layers. The option of dry/wet sanding gives more flexibility on site and helps to avoid side effects.

Environmental responsibility

BEALSTONE® Terrazzo is manufactured in Belgium and contains 97% natural materials sourced in Europe. Its formula is environmentally neutral, allowing the craftsman to paint it directly on site, which makes the product more environmentally friendly to transport and avoids waste. As its formulation encourages the use of local fillers, its environmental impact is significantly reduced.

FAQ

- BEAL INTERNATIONAL"Beal" is the only manufacturer of the BEALSTONE® product range to have registered this name. We advise you to beware of imitations and counterfeits as they do not meet the same quality requirements. BEAL INTERNATIONAL products, in particular MORTEX®, BEALSTONE® and CAPILASIL®, are protected products. They meet stringent quality standards, the results of which BEAL INTERNATIONAL guarantees. BEAL INTERNATIONAL is the sole producer of its own products.

- Products of BEAL INTERNATIONAL are distributed in Lithuania by Official Representative - MB Girinė

- Many competing companies seek to take advantage of BEAL INTERNATIONAL and the reputation of its products in order to mislead the consumer, and shall not shy away from the use of deceptive, misleading or disparaging means to sell products of significantly inferior quality or unauthorised products. Please remain vigilant for any counterfeit or imitation products and, if necessary, inform us by emailing info@girine.lt or info@beal.be.

BEALSTONE® flooring prices range from 150 to 200 €/m² excluding VAT, with a thickness of 11 mm for the poured flooring and 7 mm for the finished flooring.

This indicative price applies to the coating formula with primary fillers (marble) and approximately 100 m² of surface area with 4 external walls (without obstacles, stairs, etc.).

If stored in their original, tightly closed packaging and under the storage conditions recommended in the technical data sheets, the products can be reused for other applications. This is why we sell neutral, monochrome products. If the product has already been mixed (pigment and/or fillers added) we do not recommend storing the mixture for more than a few days.

No. We can never guarantee products that are not part of our brand because we do not control their production.

Incompatibilities can arise directly from mixing, installing, and long after installation.

It is recommended to use a flexible MS polymer type sealant (suitable for natural stone and glass) between walls and floors, floors and cladding, etc. to compensate for the movement caused by expansion of the material. The use of backing foams is recommended.

These flexible sealants do not leave any marks on the BEALSTONE® coating or other materials, unlike conventional silicone. The advantage of MS Polymer is that it is watertight. This type of sealant is used for joints that are subject to movement (expansion, etc.).

The flexible sealant must be applied before the surface is coated with protective oil.

BEALSTONE® is best finished 3 mm from the shower tray using a sealing profile and then sealing the gap with MS Polymer sealant.

The MS polymer sealant must also be applied around the water inlets (there are no special round edge profiles for this purpose).

The soft seal must be checked and replaced if necessary.

These 3 types of connections withstand regular cleaning very well.

Yes.

In any case, wiping is necessary to keep the surface clean and firm.

It is recommended to completely remove the flashing on the BEALSTONE® coating.

If the coating is protected by impregnation, the material must be sanded to the depth of penetration of the protection.

Roughen the surface to allow adhesion on the old BEALSTONE® coating.

The thickness of the layer to be wiped off will depend on how much space is left to apply the new coating.

The use of RESIDUR primer is optional, but it will facilitate the adhesion of the new BEALSTONE® coating layer.

It is necessary to carefully follow the technical data sheet of each product.

Always work on a stable, clean and dust-free surface.

Glass fibre or our BEALTEX reinforcement fabric does not guarantee adequate results as it can only withstand very small movements.

It is the fabric (reinforcement fabric) that will stretch to absorb the movements of the substrate. The BEALSTONE® product will then undergo stresses which may result in several micro cracks rather than one large crack at the original substrate crack.

It is always difficult to handle live cracks "without changing the substrate." For this reason, it is always necessary to consider the deformation joints of the substrate so that a deformation joint is created in the BEALSTONE® surface.

BEALSTONE® coating is not intended for this purpose.

The manufacturer makes no warranties for any use not covered by the technical data sheets and installation protocol. However, BEALSTONE® coating is currently undergoing studies for possible use in swimming pools.

Although BEALSTONE® is waterproof by its own means, it behaves like most natural stones (the surface is microporous). It is therefore recommended to use a protective coating for stains (wine, grease, etc.) indoors: oil, oil wax, water repellent, etc.

See our advises for protection coating.

In all cases, we recommend that you carry out tests on samples beforehand to determine the appropriate finish and protection.

When hard-to-remove stains appear on the substrate, especially on BEALSTONE® products, a capillary suction system can be tried.

Try cleaning with a soft brush and soapy water:

- 1. After spotting, moisten with lukewarm water for at least 10 minutes.

- 2. Remove the water.

- 3. Dampen again.

- 4. Place several sheets of absorbent paper, one on top of the other, flat on the stain, overlapping by 10 cm. 10 to 20 sheets may be needed.

- 5. Wet all the layers well and press out the air to ensure that the paper sheets are flat and in full contact with the surface.

- 6. Allow to dry naturally without interference. Do not create a draft.

- 7. As the surface dries, the pores of the paper open and the capillaries cause suction to pull dirt out of the substrate and onto the paper sheets.

- 8. Once the paper layers are completely dry, remove them.

- 9. Check the result.

- 10. Repeat if necessary.

If the stain originates from a small open cavity in the BEALSTONE® mineral product and the protector has not treated this cavity, the system will not be effective as the suction may only concentrate on this small cavity and not on the whole stain.

If necessary, repeat the operation.

Yes, this traditional heating method with a levelling layer and insulation is fully compatible with BEALSTONE. As with other types of coatings, precautions must be taken to ensure correct performance in relation to the substrate and temperature settings.

Background

The substrate to be applied must be dry and clean for application (see technical data sheet), and the heating must be switched off 4 days before the coating.

Where the substrate is composed of other types of materials which are not stable and/or have seams (e.g. tiles, OPAL system, etc.), the necessary precautions must be taken to avoid, as far as possible, any movement due to expansion, differences in surface and internal stresses, and sliding, i.e. to choose :

- reinforced mesh or reinforced textile matting at the joints

- A reinforcement network to be embedded in the first technical layer.

- Special textile mortar adhesion mat in corners

- Separating membranes across the surface

Temperatures

As with conventional underfloor heating, the maximum temperature should be 28-30 °C.

Start heating (2-3°C every 48 hours at steps higher than the base temperature) when the MORTEX® product is completely dry (at least 7 days). When the heating system is turned off, it is always restarted, increasing the temperature in 2-3 °C increments every 48 hours.

If for any reason (e.g. when changing the colour of the coating or when carrying out repairs) it is necessary to remove this oily aspect, it is best to remove it mechanically (if the oil is completely dry) by grinding the treated surface with a diamond disc (grain size 100-150).

(If the oil is very hard, you can go straight to section 3).

- 1. Wipe the surface with turpentine and a white cotton cloth to remove as much oil as possible.

- 2. Try again to remove as much residual oil as possible with the Vaporetto-style steam cleaner.

- 3. Scrub/sand the surface to remove any oil residue.

- Please note that if traces of oil remain, the protection will not adhere to these areas, giving the shower cover a different appearance and not being waterproof. It is therefore necessary to make sure that everything has been removed, which is quite a delicate operation.

- 4. Vacuum and wipe the surface thoroughly to remove any residual dust.

- 5. After complete drying, apply the chosen protection according to the method recommended by "Beal".

Exception: after point 3, traces of well-dried and hardened oil may remain on the entire surface. In principle, the varnish should be able to adhere to them, but we have no tests in this respect.

If the BEALSTONE® product is structured and not perfectly flat, it will not be possible to remove all the oil from the small cavities without damaging the last layer of BEALSTONE® product.

We therefore recommend sanding the entire surface until a perfectly smooth surface with no open pores is obtained.

The abraded surface and its immediate surroundings must be thoroughly cleaned and removed of dust.

The surface must be treated with the chosen protection agent according to the installation protocol.

If fresh repellent oil is available, tests can be carried out with turpentine.

If for any reason (e.g. when changing the colour of the coating or when carrying out repairs) it is necessary to remove this repellent aspect, it is best to remove it mechanically (if the repellent is completely dry) by grinding the treated surface with a diamond disc (grain size 100-150).

(If the oil repellent layer is very hard, you can go straight to section 3).

- 1. Wipe the surface with turpentine and a white cotton cloth to remove as much of the oil repellent as possible.

- 2. Using a vaporetto-style steam cleaner, try again to remove as much of the oil-repellent residue as possible.

- 3. Scrub/sand the surface to remove any oil-repellent residue.

- Please note that if traces of oil repellents remain, the varnish will not stick to these areas and the shower will not be waterproof. It is therefore necessary to make sure that everything has been removed, which is quite a delicate operation.

- 4. Vacuum and wipe the surface thoroughly to remove all traces of dust.

- 5. Once completely dry, apply the chosen protection according to the method recommended by Beal.

Exception: after point 3, traces of well-dried and hardened oil repellent may remain on the entire surface. In principle, the varnish should be able to adhere to them, but we have no tests in this respect.

If the BEALSTONE® product is structured and not perfectly flat, it will not be possible to remove all the oil repellents from the small cavities without damaging the last layer of BEALSTONE® product.

We therefore recommend sanding the entire surface until a perfectly smooth surface with no open pores is obtained.

The abraded surface and the immediate surroundings must be thoroughly cleaned and dusted.

The surface must be treated with the chosen protection agent according to the installation protocol.

If fresh repellent oil is available, tests can be carried out with turpentine.